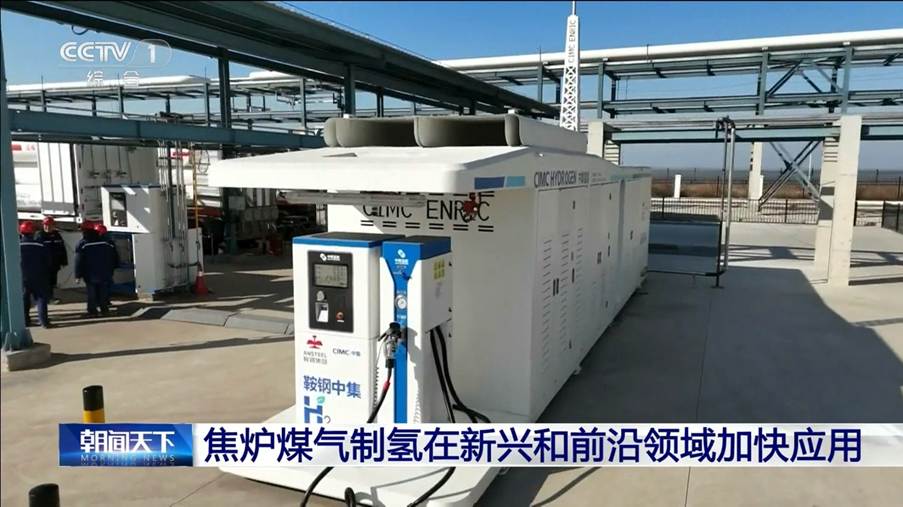

(25 November 2025 – Hong Kong) CIMC Enric Holdings Limited together with its subsidiaries (“CIMC Enric” or the “Group”) (Stock Code: 3899.HK), is pleased to announce that the Coke Oven Gas Integrated Utilization Project (the “Linggang project” “the Project”), has officially commenced production. The Project was jointly invested and constructed by CIMC Enric and Angang Steel Energy Technology Co., Ltd. (“Angang Steel Energy Technology”). The project supports Lingyuan Iron & Steel Group’s (a subsidiary of Angang Steel Energy Technology) coke oven equipment upgrade and green development renovation initiative, integrating coke oven gas-to-LNG, hydrogen (liquid ammonia) production.

As China’s first project to realize complete conversion of coke oven gas, it is designed to produce 140,000 tons of LNG, 24 million cubic meters of blue hydrogen, and 60,000 tons of synthetic ammonia annually. These clean energy products will meet the demand for green fuels in local transportation, industrial production, and other scenarios, marking a breakthrough in the high-value utilization of industrial by-products.

A Proven Collaborative Model, Accelerating Industrial Green Transition

Located in Lingyuan, Chaoyang City, Liaoning Province, the Linggang Steel Project is the second steel-coke integration collaboration between CIMC Enric and Angang Steel Energy Technology in Liaoning. Its successful commissioning underscores growing market recognition of the economic and environmental value of this pioneering model, which boasts strong replicability and provides a practical pathway for traditional enterprises to deepen integration with regional energy transition efforts.

Notably, the Group’s first steel-coke integration project — launched in Bayuquan, Yingkou, Liaoning in 2024 — has achieved stable and successful operation for over a year, laying a solid foundation for the replication and scaling of this model.

In Northeast China, the traditional industrial base, efforts to advance clean energy adoption have primarily focused on new energy power generation (e.g., offshore wind, photovoltaic, and biomass projects). However, traditional industries such as steelmaking have long been associated with emission reduction rather than acting as “direct producers” of clean energy.

CIMC Enric’s innovative “steel-coke integration” model transforms coke oven gas — a by-product of steel production — into high-value clean energy (including LNG, hydrogen, and liquid ammonia) for application in steel transportation, chemical production, and other local industrial scenarios. This model directly links the traditional steel industry to regional clean energy development, driving Liaoning Province’s industrial green transition and setting a precedent for cross-industry synergy.

Significant Environmental Benefits with CO2 emission reduced & Industry-Leading Project Execution,

Covering an area of approximately 27.9 hectare, the Linggang Steel Project features state-of-the-art production capabilities: the hydrogen produced boasts a purity of 99.9999% (meets hydrogen fuel cell standards with negligible impurities); LNG will replace diesel as fuel for local heavy-duty trucks, vessels, and locomotives, and substitute coal for power plants and industrial users to reduce carbon emissions; liquid ammonia (for peak shaving) will serve sectors including agricultural fertilizers, chemical producers, refrigeration, and metallurgy.

From an environmental perspective, the project’s integrated utilization of coke oven gas is expected to deliver substantial emission reductions annually: 402,500 tons of carbon dioxide, 226.3 tons of sulphur dioxide, and 1,747.2 tons of nitrogen oxides.

Notably, the project was delivered as a turnkey solution by CIMC Enric Engineering Technology Co., Ltd., a subsidiary of the Group, encompassing core process design, overall installation, and construction. Completed in just 10 months, the project sets a new industry record for construction efficiency and establishes a benchmark for similar initiatives. Key equipment, including LNG storage tanks, was also supplied by CIMC Enric, demonstrating the Group’s end-to-end capabilities in the clean energy value chain.

Digital Upgrade: Enabling Full-Lifecycle Carbon Management

The Linggang Steel project is integrated with CIMC Enric’s self-developed intelligent interconnected digital platform, which leverages most advanced digital technologies, such as artificial intelligence (AI), the Internet of Things (IoT), and cloud computing.The platform integrates full-process data across energy production, storage, transportation, and customer-focused comprehensive energy services, as well as lifecycle carbon emission data.

Through end-to-end data collection from intelligent devices, the platform enables full-lifecycle carbon management, capturing real-time Scope 1, 2, and 3 emission data across the entire industrial chain (upstream production, midstream transportation, and downstream customer scenarios). This supports the project and its upstream/downstream partners in achieving their carbon reduction targets.

In operations, the platform integrates situational awareness and model algorithms to ensure safe plant operation, driving the energy system toward end-to-end intelligence, greenification, and enhanced safety.

Building on the success of the Angang Yingkou steel-coke integration project, which established the steel industry’s first “hydrogen closed-loop demonstration benchmark” (with hydrogen-fueled clean energy heavy-duty trucks supporting daily steel transportation), CIMC Enric’s digital management platform serves as an “intelligent command center,” creating a scalable digital model for the clean energy transition of traditional industries.

Looking Ahead: Scaling the Model Globally

The official operation of the Linggang Steel Project will inject powerful “green momentum” into the transformation of local traditional industries. Leveraging CIMC Enric’s leading capabilities in clean energy key equipment, core processing technologies, and integrated services, the project deepens collaboration with steel enterprises to promote high-value utilization of coke oven gas, foster the development of local hydrogen and LNG industrial ecosystems, and support steel plants in aligning with Northeast China’s energy transition strategy.

Going forward, CIMC Enric will continue to accelerate the replication of this successful model across Liaoning, other domestic regions, and international markets, contributing to global industrial decarbonization efforts.